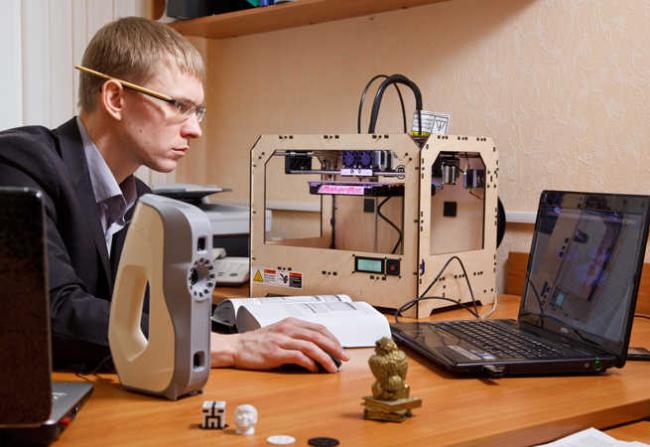

FabLab of VyatSU is a laboratory with a set of equipment and specialized software for a digital manufacturing that allows creating prototypes of a variety of products and devices, to implement interesting inventive ideas, and develop engineering creativity.

The laboratory provides services for pilot testing of new products and projects. Interested parties are offered a complete cycle of a chain production or some separate services:

- computer-aided design and modeling of a product (CAD and CAE);

- production of cosmetic (mock-up) prototypes;

- production of functional prototypes;

- design and manufacturing of tooling for mass production;

- research and development activities;

- technological audit and technical expertise of investment projects.

Suchlike centers operate not only educational, but prototyping center’s functions as well.

The main principles of scientific activity are:

- integration of fundamental and applied research and development with the educational process to increase the quality of training;

- commercialization of the research results with a focus on the real economy;

- involvement of students, post-graduate students, doctoral students and industrial specialists from Russian scientific centers and abroad.

FabLab Community

Open access to the means of production

Joint work on innovative projects

Seminars and master classes

Installation work

Popular science events

FabLab offers support with:

Expertise and consultations to companies for new technology projects implementation.

Product Requirements Documents for tenders for equipment supply.

Contracts for equipment supply.

Product Requirements Documents and agreements with companies to develop project documentation.

Licenses, permits and certificates at state authorities.

Data collection and analysis for analytical reports and surveys on technology development.

New products design and upgrading of machinery, vehicles, and equipment of the current manufacturing.

Advanced engineering development and advanced materials.

Project development of new experimental and industrial installations, optional equipment and accessories within the reconstruction of facilities, production automation and mechanization of labor-intensive processes.

Improving the level of unification, standardization and certification of developed designs.

Ensuring compliance with the new and modernized technical specifications, standards, requirements for labor protection and safety standards.

Technical justification of new design developments and their advantages in comparison with previously manufactured ones.

Implementation of prospective and current plans for introduction and development of new technology.

Design preparation of manufacturing.

Research, development and technological works.

Manufacturing of prototypes and their experimental verification, completion of installation and production of the first industrial samples.

Design solutions to improve products quality and reliability, their technological and environmental level, to reduce their costs, labor and material expenses.

Installation, testing, and starting-up of new product designs.

Proposals for reconstruction, re-equipment, intensification of production, and its efficiency increasing.

Design technology for innovations and inventions accepted for implementation.

Preparation of opinions on the most sophisticated innovations, as well as the preparation of opinions on the draft standards and other design documentation from the third parties.

Consultations on specific engineering and technological problems.